General availability of used central-impression (CI) flexographic presses for flexible packaging, commercial print, film, foil, paper, and converting applications. Equipment includes Uteco Emerald/Onyx/Sapphire EVO, W&H Miraflex/Novoflex, and other CI/flexo lines from Bobst, PCMC, Flexotecnica, Rotomec, Cerutti, Carraro, Bielloni, Stevens, Wolverine, Victory Kidder, Gloucester, and more.

CI flexo presses are widely used for high-speed printing on film, polyethylene, polypropylene, laminates, paper, board, and specialty substrates. These systems are known for tight registration, consistent impression, fast changeovers, advanced web handling, and high-quality process printing suitable for packaging, labels, and converting operations.

CI FLEXOGRAPHIC PRESSES – PACKAGING & COMMERCIAL PRINTING

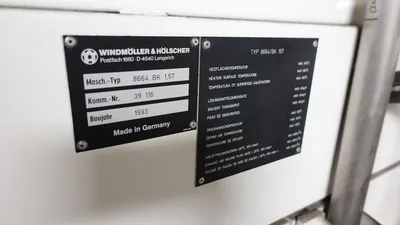

Manufacturers: Uteco, Windmöller & Hölscher (W&H), Bobst, PCMC, Flexotecnica, Rotomec, Cerutti, Carraro, Bielloni, Stevens, Wolverine, Victory Kidder, Gloucester

PRINTING CAPACITY

-----------------------------------------------------

Colors: 6–12 color CI configurations

Repeat Lengths: Typical 12"–32" (varies by model)

Web Width: ~800–1600 mm common; large-format available

Speed Range: ~300–600 m/min depending on press series

SUBSTRATES

-----------------------------------------------------

Flexible packaging films (PE, PP, BOPP, PET)

Paper & coated papers

Aluminum foil & laminates

Specialty packaging substrates

Commercial film printing

CORE SYSTEMS

-----------------------------------------------------

CI Drum: precision-ground, temperature-controlled

Anilox Technology: sleeve or conventional anilox systems

Plate Change: quick-change sleeves, automatic mounting options

Drying: hot air, IR, and energy-optimized drying tunnels

Tension: automated tension and web-guiding systems

Register: camera-based closed-loop register & inspection

Inking: enclosed doctor blades, viscosity/temperature controls

WEB HANDLING & AUXILIARY

-----------------------------------------------------

Shaftless or turret winders

Unwind/rewind with automatic splicing

Corona/Plasma treatment

Web cleaners, static control

Laminating & coating modules (on equipped lines)

Slitting or converting integration (model dependent)

APPLICATIONS

-----------------------------------------------------

Flexible packaging

Food packaging

Shrink films

Labels

Commercial flexo printing

Converting & laminating operations

• CI drum systems (8–10 colors common; some up to 12)

• Shaftless unwinds & rewinds

• Automatic tension control

• Closed-loop register systems

• Sleeve technology for anilox & plate changes

• Web cleaning & corona treatment systems

• Drives: servo-driven or gear-driven depending on year

• Turret or single-position winders

• Dryers: hot air / IR / energy-efficient drying modules

• Inspection cameras, viscosity control, and inking systems

• Laminating, coating, slitting, or converting integration options

• Ink circulation systems & auto wash-up features

• Suitable for film, foil, paper, laminates, and flexible packaging

We use cookies to improve your experience. Privacy Policy.