Motion Control & Automation

State-of-the-art upgrades for drives, PLCs, HMIs, and motion control automation for printing, packaging, and converting business.

Overview

We upgrade drives, PLCs, HMIs, and motion control with planned installation and factory testing, so you get faster diagnostics, less obsolescence risk, and steadier output. Siemens-centric, multivendor-capable—delivered with documentation, backups, and operator hand-off.

Quick Facts

- 30+ years, global projects delivered

- Siemens-centric; multivendor capable

- Documentation: drawings, backups, reports

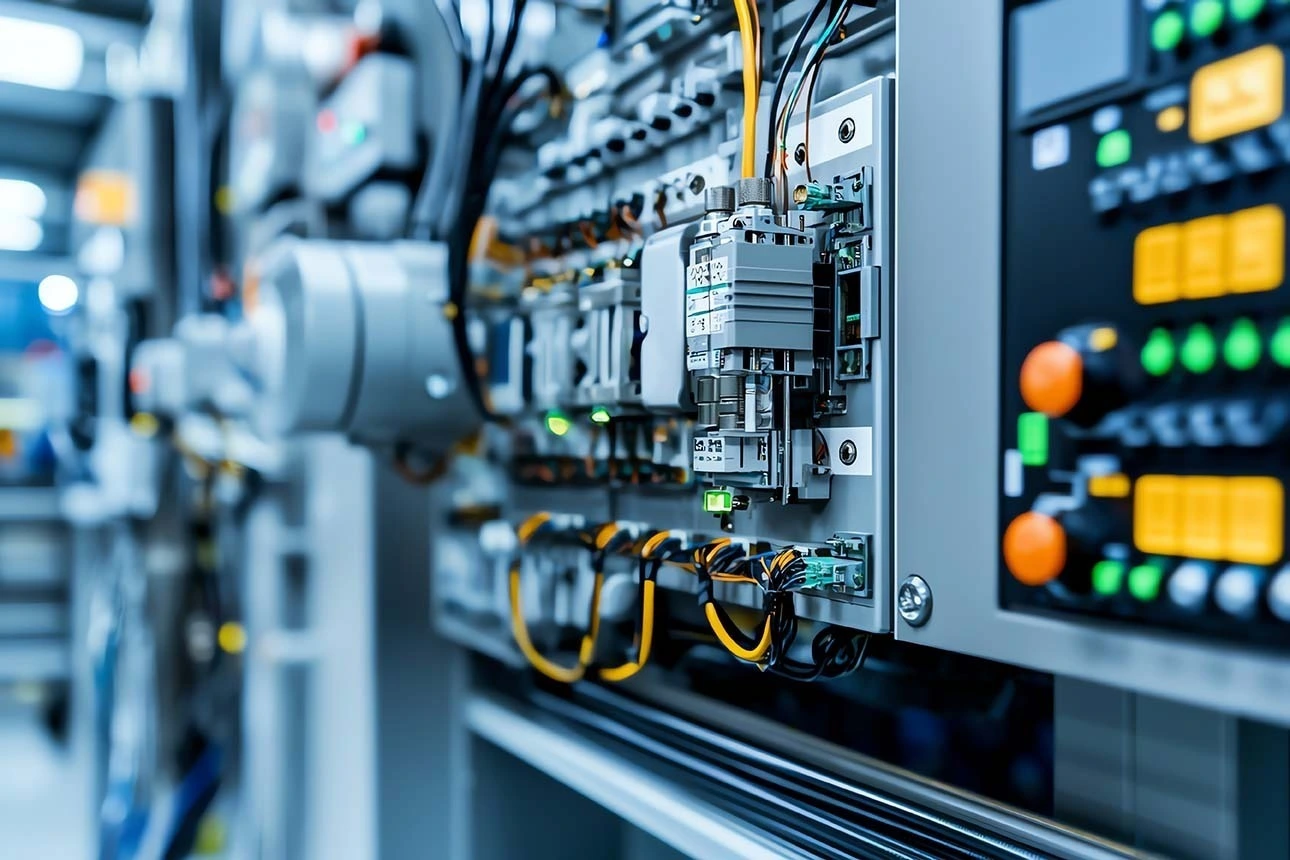

Core Services

Electrical engineering

feasibility reviews and performance-based conversions

AC & servo drive upgrades

modern drive solutions and engineering services

Motion control

replace drives/PLCs and standardize platforms

Operator consoles / HMI

streamlined screens, alarms, and user workflows

Remote diagnostics

diagnosing and repairing common problems

Turnkey installations

from design to build-out, installation, and commissioning

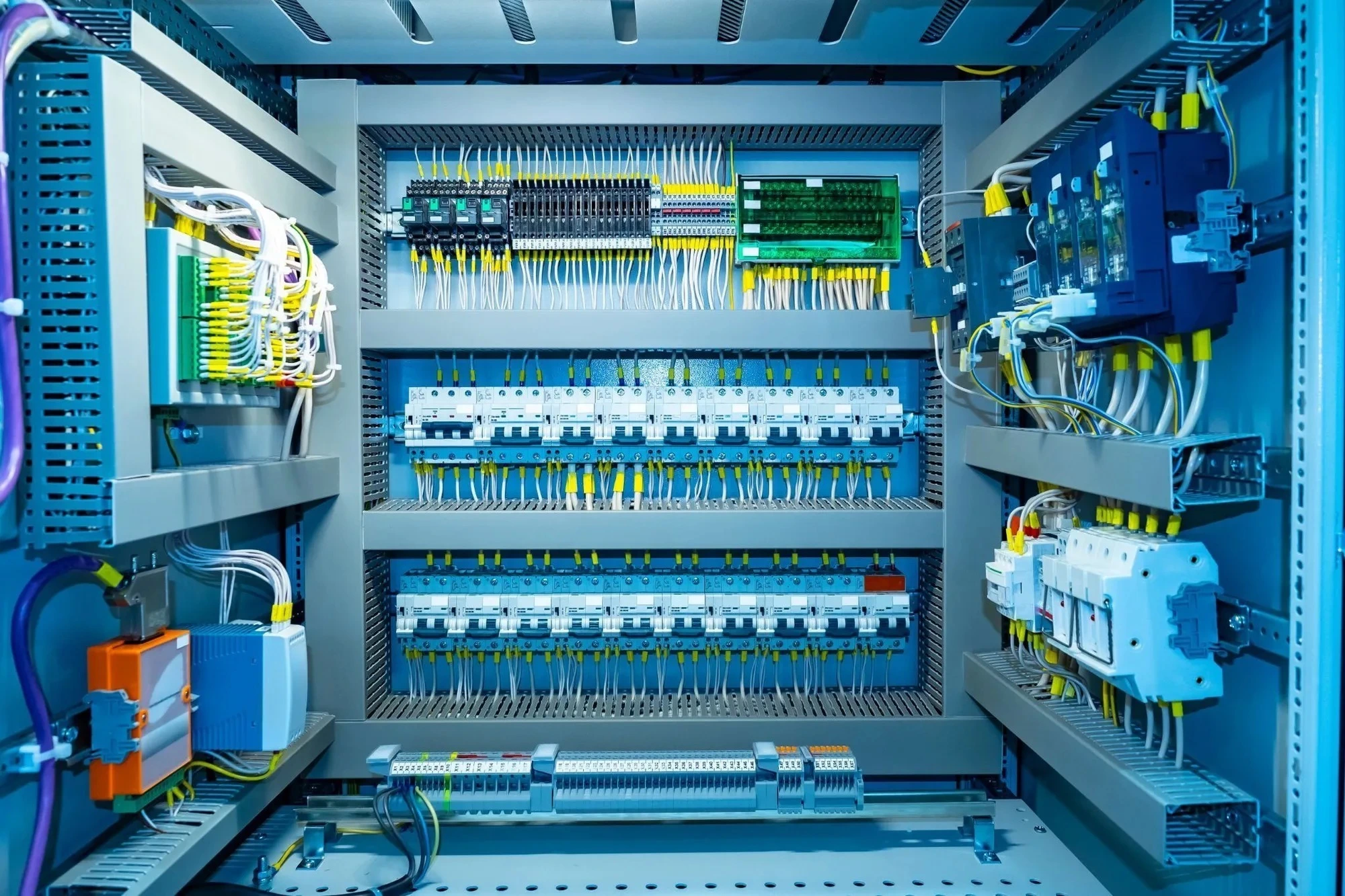

Panel fabrication

custom control panels (design, build, wire, label), factory testing with documentation, and install support as needed

System integration

unify drives/PLCs/HMIs, safety and I/O; commissioning and operator training

Motion Control Enhancements

stability and accuracy for register, tension, and servo applications

Remote Support

diagnosing and repairing common problems remotely per service agreement.

Drive Upgrades / Replacements

Engineered upgrades for printing, packaging, and converting lines with startup services and commissioning.

Press & Auxiliary Equipment

Print units, infeeds, chills, folders, splicers, rewinders- Full press-line drive replacements & upgrades

- Installation, startup, and tuning

Deliverables

Hardware, panels, engineering, buildout.Installation, commissioning, and support

Configured Solutions

- Replacements and tuning

- Standardized parameters

- Updated PLC/drive platforms

- I/O alignment and commissioning plan

- Feedback strategy and section coordination

- Stability improvements

- Screens and alarms

- Recipes and user roles

Our Expertise

- Web offset, sheetfed, digital inkjet

- Bindery/finishing, inserters/mailroom

- Packaging and converting lines

- Plant support systems

- From single-machine upgrades to multi-line programs

Applications

- Printing press & production lines

- Converting & packaging automation

- Finishing & material handling

Process

Discovery & valuation → Site review → Design & scope (SOW) → Build & test → Installation & commissioning → Documentation & hand-off

What You Receive

- As-built electrical drawings

- Updated I/O lists

- PLC/HMI project files

- Drive backups & report

- Operator notes

- Acceptance checklist

Support Options

Warranty

- Warranty covered items

- Commissioning budget

- T&M on-site service call

Remote Support

- T&M remote service rates

- Rapid diagnostics

- Scheduled windows

Typical Outcomes

- Faster diagnostics and recovery

- Lower obsolescence risk

- Reduced machinery disruption risk

- Modern technology with support options

Assumptions & Limits

Project Assumptions

What we assume for quoting & delivery- Scope/deliverables defined in SOW

- Performance gains depend on mechanical condition

- Remote access requires approved IT protocols and accessibility

- Safety compliance per SOW for new equipment

- Rigging, freight, and site trades by others

Quote Checklist

- Machine/line: make, model, year + machine & controls photos

- Controls: drives/PLC/HMI; I/O counts

- Mechanics: motors/HP, gearboxes, web width, cut-off

- Goals: increased reliability, diagnostics, data/traceability

- Constraints: equipment age, feasibility, timeframe, budget