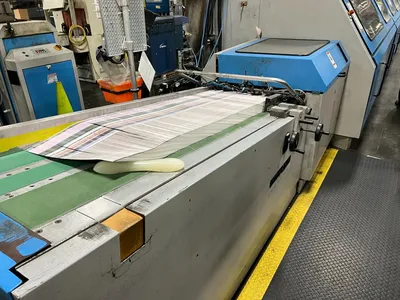

General availability of Müller Martini Corona perfect binders, including C12, C13, C15, and C18 models. These high-speed softcover binding systems are widely used for books, catalogs, manuals, educational materials, and commercial finishing applications.

The Corona platform is known for speed, automation, and versatility, offering production rates up to 12,000 cycles/hour, automated make-ready systems (ASIR/ASAC), and flexible book-format capability from thin booklets to thick catalogs up to 60mm.

Typical configurations include gathering sections, stream feeders, overhead cranes, cooling towers, binder sections with multiple clamps, and integrated three-knife trimmers such as Orbit or Zenith. Many systems also support hotmelt and PUR gluing, automated caliper control, and inline finishing delivery options.

These binders remain one of the most proven and reliable perfect binding solutions in the world, with a large installed base and strong long-term parts support.

MÜLLER MARTINI CORONA PERFECT BINDERS

Models: C12, C13, C15, C18

Application: High-speed softcover perfect binding

GENERAL SPECIFICATIONS (VARIES BY MODEL)

----------------------------------------

Max Speed:

- C12 / C13: Up to 12,000 cycles/hour

- C15: Up to 15,000 cycles/hour (model-dependent)

- C18: Up to 18,000 cycles/hour (high-speed configuration)

Book Thickness: 2–60 mm

Max Book Size (W x H): ~305 x 510 mm

(up to ~320 x 430 mm depending on line/trimmer)

Min Book Size (W x H): ~100 x 148 mm

(some lines ~140 x 100 mm)

Clamps: 24, 26, 35, or 42 clamps depending on model/line

Stations: 18, 21, or custom gathering counts

Gluing Systems:

- Hotmelt spine & side gluing standard

- PUR capability available on many lines

- Premelters: PM 30, PM 80 (varies by configuration)

Automation:

- ASIR (Automatic Signature Recognition)

- ASAC (Automatic Self-Adjusting Calipers)

- Optional BDC (Book Data Center)

- Automated make-ready options for size changes

Finishing & Trimming:

- Typically includes inline Müller Martini Orbit or Zenith 3-knife trimmer

- Fully automated trimming for continuous softcover production

- Cooling towers, stackers, and conveyor deliveries available

Feeding Components:

- Stream feeders

- Overhead cranes

- Gathering sections (18–21 stations typical)

Delivery Options:

- Belt and stacker deliveries

- Inline finishing

- Waste removal/extraction systems

Applications:

- Books

- Catalogs

- Brochures

- Commercial softcover production

- Educational & publishing markets

Notes:

Specifications vary by exact Corona model (C12, C13, C15, C18) and line configuration.

C18 is the fastest model in the series with up to 18,000 IPH capability.

• Corona C12, C13, C15, C18 (18,000 IPH) models

• Stream feeders

• Gathering sections (18–21 stations)

• Overhead cranes

• Cooling towers

• Binder section with 24–42 clamps

• ASIR & ASAC automated make-ready

• Hotmelt & PUR gluing

• Orbit/Zenith inline trimmers

• Stacker & belt deliveries

• Waste extraction systems

• Premelters (PM 30 / PM 80)

• Optional Book Data Center (BDC)

We use cookies to improve your experience. Privacy Policy.